Health

Maintain Your Muzzleloader: Essential Cleaning Tips for Hunters

As hunting seasons wind down, it’s crucial for hunters to ensure their muzzleloaders remain in optimal condition. The cleaning and maintenance of these firearms, particularly in-line designs, are essential to avoid issues like misfires and delayed ignition.

The Shift to In-Line Muzzleloaders

The introduction of in-line muzzleloaders in the early 1980s transformed the hunting landscape. Innovations in ignition systems made these firearms more accessible and reliable. According to data, approximately 95% of deer taken in the United States each year are harvested using in-line muzzleloaders. This trend extends to larger game, such as bear and elk, indicating a significant shift away from traditional sidelock flintlock and percussion guns.

Many hunters, including myself, have embraced this change. My journey began with a MK-85 from Knight Rifles in 1985, and since then, I’ve used various models from manufacturers like Thompson/Center and CVA. The ease of use and maintenance of in-line designs has greatly contributed to their popularity, making them a preferred choice among modern hunters.

Cleaning and Maintenance Essentials

Proper maintenance of a muzzleloader includes a focus on the breech plug, one of the key components that enable reliable firing. In-line breech plugs screw in and out, allowing for straightforward cleaning. They typically feature a primer pocket and fire channel that direct the spark into the powder charge.

Neglecting this simple task can lead to significant problems, such as misfires or seized plugs. Many hunters face these issues due to the buildup of residues, even from seemingly clean-burning substitutes. Most muzzleloading powders are hygroscopic, meaning they absorb moisture, which can lead to crusting and ultimately, a seized plug.

Cleaning the breech plug is a simple process. Start by removing it and cleaning the threads, primer pocket, and fire channel. Soaking the plug in a dedicated solution, such as Birchwood Casey No. 77 or Thor’s MZ Breech Plug Solution, can effectively break down residue. A small brush can help scrub away stubborn deposits, while compressed air is useful for removing any lingering moisture.

After cleaning, it is important to reinsert the plug using an anti-seizing lubricant designed for high heat, such as Thompson/Center’s Gorilla Grease. Following a regular maintenance regimen will help prevent ignition issues and ensure your muzzleloader is always ready for the next hunting season.

Another critical aspect of maintenance is the firing pin in break-open models. Residue or rust can cause it to stick, so it’s advisable to apply a small amount of oil and operate the hammer to ensure it moves freely.

For long-term storage, it’s best to position muzzleloaders muzzle-end down. This prevents cleaning solvents or oils from seeping into the breech plug. A safe equipped with a dehumidifier is ideal, but if that is not available, a hard gun case with reusable desiccant packs can effectively manage moisture levels.

Although big game hunting seasons may be coming to a close, ensuring that your muzzleloader is clean and properly stored is vital. Taking care of these firearms not only extends their lifespan but also guarantees they perform as expected when the time comes to hunt again.

-

Science1 month ago

Science1 month agoUniversity of Hawaiʻi Leads $25M AI Project to Monitor Natural Disasters

-

Science2 months ago

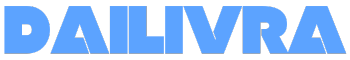

Science2 months agoInterstellar Object 3I/ATLAS Emits Unique Metal Alloy, Says Scientist

-

Science2 months ago

Science2 months agoResearchers Achieve Fastest Genome Sequencing in Under Four Hours

-

Business2 months ago

Business2 months agoIconic Sand Dollar Social Club Listed for $3 Million in Folly Beach

-

Politics2 months ago

Politics2 months agoAfghan Refugee Detained by ICE After Asylum Hearing in New York

-

Business2 months ago

Business2 months agoMcEwen Inc. Secures Tartan Lake Gold Mine Through Acquisition

-

Health2 months ago

Health2 months agoPeptilogics Secures $78 Million to Combat Prosthetic Joint Infections

-

Science2 months ago

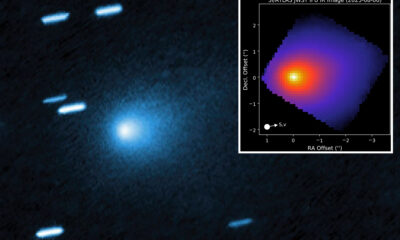

Science2 months agoMars Observed: Detailed Imaging Reveals Dust Avalanche Dynamics

-

Lifestyle2 months ago

Lifestyle2 months agoJump for Good: San Clemente Pier Fundraiser Allows Legal Leaps

-

Health2 months ago

Health2 months agoResearcher Uncovers Zika Virus Pathway to Placenta Using Nanotubes

-

Entertainment2 months ago

Entertainment2 months agoJennifer Lopez Addresses A-Rod Split in Candid Interview

-

World2 months ago

World2 months agoUS Passport Ranks Drop Out of Top 10 for First Time Ever