Science

Researchers Slash CO2 Emissions in Fuel Synthesis with Iron Catalysts

A team of scientists has achieved a breakthrough in reducing carbon dioxide emissions during fuel synthesis, cutting CO2 production by over 99% in a process that converts synthesis gas into liquid hydrocarbons. This advancement, detailed in a study published on November 4, 2025, in the journal Science, focuses on modifying iron-based catalysts used in Fischer–Tropsch synthesis (FTS), a key method in the petrochemical industry.

Fischer–Tropsch synthesis is essential for transforming synthesis gas—comprised of carbon monoxide (CO) and hydrogen (H2)—into liquid fuels. The research from a group led by Yi Cai from China introduces a novel approach by incorporating trace amounts of bromomethane (CH3Br) into the syngas feed, dramatically improving the process’s environmental impact.

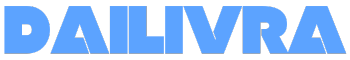

With traditional methods, CO2 selectivity during this conversion typically ranges from 18% to 35%. The introduction of bromomethane reduced these emissions to nearly zero, while simultaneously increasing olefin production to an impressive 85%, resulting in an olefin-to-paraffin ratio of 13:1. This marks a tenfold improvement over previous catalysts that yielded a ratio of only 1.3:1.

The research highlights a pressing need for greener energy technologies, as fossil fuels still constitute more than 80% of global energy consumption. The team aims to enhance both the efficiency and sustainability of the FTS process, which has been integral to the petrochemical industry since its inception by German chemists Franz Fischer and Hans Tropsch in the 1920s.

More than two-thirds of the global FTS operations employ iron-based catalysts, which produce approximately 15.7 million tons of liquid hydrocarbons annually. These catalysts are favored for their cost-effectiveness and natural abundance. However, they have historically been associated with unwanted side reactions that lead to excessive CO2 emissions.

Previous efforts to mitigate CO2 production involved coating iron catalysts with hydrophobic materials or graphene, which only succeeded in reducing selectivity to below 13%. Research on iron carbide catalysts managed to lower CO2 selectivity to around 10%, but their effectiveness in CO conversion and olefin production remained limited.

In this latest study, the researchers identified that adding bromomethane directly to the syngas during the catalytic process formed surface-bound bromine entities. This innovation blocked two unwanted reactions—water-gas shift (WGS) and Boudouard reactions—that typically produce water and CO2 as byproducts. Additionally, this modification facilitated the easier release of olefins from the catalyst surface, preventing their conversion into less valuable products.

The modified iron catalyst demonstrated remarkable stability, functioning effectively for over 450 hours without loss of performance. This practical strategy is compatible with a variety of iron-based FTS catalysts, including those used in commercial applications.

The implications of this research extend beyond the laboratory, offering a pathway toward carbon-neutral conversion of coal and syngas. By bridging the gap between fossil fuel chemistry and climate sustainability, this work represents a significant step forward in the quest for environmentally responsible energy solutions.

This article is based on research conducted by Yi Cai and colleagues, as reported in Science. The findings underscore the potential for innovative approaches to enhance the sustainability of traditional energy processes, which continue to play a critical role in global energy consumption.

-

Science3 weeks ago

Science3 weeks agoInterstellar Object 3I/ATLAS Emits Unique Metal Alloy, Says Scientist

-

Politics3 weeks ago

Politics3 weeks agoAfghan Refugee Detained by ICE After Asylum Hearing in New York

-

Business3 weeks ago

Business3 weeks agoIconic Sand Dollar Social Club Listed for $3 Million in Folly Beach

-

Health3 weeks ago

Health3 weeks agoPeptilogics Secures $78 Million to Combat Prosthetic Joint Infections

-

Science3 weeks ago

Science3 weeks agoResearchers Achieve Fastest Genome Sequencing in Under Four Hours

-

Lifestyle3 weeks ago

Lifestyle3 weeks agoJump for Good: San Clemente Pier Fundraiser Allows Legal Leaps

-

Science3 weeks ago

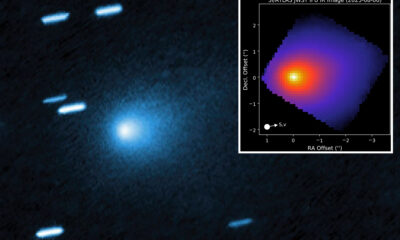

Science3 weeks agoMars Observed: Detailed Imaging Reveals Dust Avalanche Dynamics

-

World3 weeks ago

World3 weeks agoUS Passport Ranks Drop Out of Top 10 for First Time Ever

-

Health3 weeks ago

Health3 weeks agoResearcher Uncovers Zika Virus Pathway to Placenta Using Nanotubes

-

Entertainment3 weeks ago

Entertainment3 weeks agoJennifer Lopez Addresses A-Rod Split in Candid Interview

-

Business3 weeks ago

Business3 weeks agoSan Jose High-Rise Faces Foreclosure Over $182.5 Million Loan

-

Top Stories3 weeks ago

Top Stories3 weeks agoChicago Symphony Orchestra Dazzles with Berlioz Under Mäkelä