Science

University of Florida Chemists Develop Revolutionary Material Technique

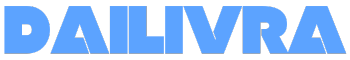

Chemists at the University of Florida have introduced an innovative technique to create highly porous materials from common plastics, potentially transforming industries such as electronics and battery manufacturing. The method, described as an “addition-by-subtraction” process, focuses on removing components rather than adding new materials.

Brent Sumerlin, Ph.D., a professor of chemistry and the senior author of the study, likened the technique to the artistry of sculpting. “It’s like what a sculptor might do with stone, where you gradually subtract more and more until you have what you want,” he explained. This novel approach enables the creation of pores from within the material, a feat Sumerlin believes would be unattainable by other methods.

The porous materials generated through this technique are particularly valuable for applications in energy storage and water purification. As demand grows for efficient batteries and natural water filters, Sumerlin and his team’s findings, published in the journal ACS Central Science, highlight a significant advancement in materials science.

Innovative Process Behind Material Creation

The new method emerged from Sumerlin’s prior research aimed at improving plastic recycling. By studying how different plastics decompose at varying temperatures, his laboratory discovered a unique opportunity to engineer new materials. For their experiments, the team combined the building blocks of Plexiglass and Styrofoam, which typically do not mix well.

When exposed to the appropriate temperature, components resembling Plexiglass evaporated, leaving behind polystyrene. This process resulted in the formation of trillions of tiny pores, each smaller than a virus. Remarkably, a single gram of this material can exhibit a surface area comparable to that of a full-sized tennis court.

“Surface area is king in advanced manufacturing,” Sumerlin noted. The fine structure created by this technique could serve as a mesh in wastewater purification systems and provide high-performance membranes crucial for many batteries.

Broad Applications and Future Implications

As industries increasingly focus on separating materials efficiently, Sumerlin emphasizes that this new crafting method could cater to various sectors, all originating from the fundamental goal of enhancing plastic recycling. “This just shows how basic research in one area can inform new applications in a completely different area,” he stated.

The implications of this research extend beyond immediate applications in electronics and energy storage. The ability to create effective porous materials from basic plastics could revolutionize how industries approach manufacturing and sustainability.

With a patent application filed for this innovative technique, Sumerlin’s work signals a promising future in materials science, paving the way for further exploration and application of these materials across multiple fields.

For those interested in the complete details, the study is documented in the article by Kaden C. Stevens et al., titled “Depolymerization as a Design Strategy: Depolymerization Etching of Polymerization-Induced Microphase Separations,” published on November 4, 2025. The full study is accessible through ACS Central Science.

-

Science3 weeks ago

Science3 weeks agoInterstellar Object 3I/ATLAS Emits Unique Metal Alloy, Says Scientist

-

Politics3 weeks ago

Politics3 weeks agoAfghan Refugee Detained by ICE After Asylum Hearing in New York

-

Business3 weeks ago

Business3 weeks agoIconic Sand Dollar Social Club Listed for $3 Million in Folly Beach

-

Health3 weeks ago

Health3 weeks agoPeptilogics Secures $78 Million to Combat Prosthetic Joint Infections

-

Science3 weeks ago

Science3 weeks agoResearchers Achieve Fastest Genome Sequencing in Under Four Hours

-

Lifestyle3 weeks ago

Lifestyle3 weeks agoJump for Good: San Clemente Pier Fundraiser Allows Legal Leaps

-

Health3 weeks ago

Health3 weeks agoResearcher Uncovers Zika Virus Pathway to Placenta Using Nanotubes

-

Science3 weeks ago

Science3 weeks agoMars Observed: Detailed Imaging Reveals Dust Avalanche Dynamics

-

World3 weeks ago

World3 weeks agoUS Passport Ranks Drop Out of Top 10 for First Time Ever

-

Business3 weeks ago

Business3 weeks agoSan Jose High-Rise Faces Foreclosure Over $182.5 Million Loan

-

Entertainment3 weeks ago

Entertainment3 weeks agoJennifer Lopez Addresses A-Rod Split in Candid Interview

-

Top Stories3 weeks ago

Top Stories3 weeks agoChicago Symphony Orchestra Dazzles with Berlioz Under Mäkelä