World

Boeing Launches Wing Assembly for 777-8F Freighter, Set for 2028

Boeing has commenced wing assembly for the highly anticipated 777-8F Freighter, heralded as the world’s most capable twin-engine cargo aircraft. This development signifies a crucial milestone in the Boeing 777X freighter program, showcasing the company’s commitment to enhancing its cargo capabilities. The first wing spars, each exceeding 100 feet, have been assembled alongside corresponding skin panels at Boeing’s Composite Wing Center located in Everett, Washington.

In parallel with Boeing’s efforts, major assembly operations are progressing in Japan, with Mitsubishi Heavy Industries leading the effort. Other key Japanese manufacturers, including Kawasaki and Subaru, are also playing vital roles in the assembly process. This collaborative approach highlights the global nature of aircraft production, as Boeing aims to bolster its position in the competitive cargo market.

Production Timeline and Market Impact

The initiation of wing assembly comes after Boeing announced a delay in the 777-8F’s entry into service, now scheduled for 2028. This postponement aligns with plans to cease production of the Boeing 767 freighter by 2027, significantly altering the landscape of widebody cargo aircraft. The move raises concerns about the industry’s ability to meet growing demand as older models begin to retire.

Boeing’s latest update indicates substantial progress in wing assembly, with the manufacture of wing spars and concurrent fabrication of wing skins and stringers at the Everett facility. Reports from trade sources confirm the successful completion of robotic drilling on the initial spar, marking a significant achievement for the production team. This milestone is crucial for ramping up to the anticipated first deliveries in 2028.

Strategic Significance for Boeing

The commencement of wing assembly underscores the maturation of a strategically vital platform for Boeing. The 777-8F incorporates advanced composite wings and the cutting-edge GE9X propulsion system, aiming to solidify Boeing’s leadership in the widebody freighter market. Historically, models such as the Boeing 747-400F and Boeing 777F have made profound impacts on cargo transport, establishing Boeing as a trusted name in the industry.

From a commercial perspective, the delay in service entry compresses the timeline for airlines transitioning from the Boeing 767F and 777F to the more advanced 777-8F. This situation exposes Boeing to risks as competitors, particularly the Airbus A350F, gain traction among airlines seeking improved capabilities. The successful execution of production milestones is essential for maintaining customer confidence and securing future orders.

Financially, Boeing faces challenges related to certification delays and potential cost overruns. The certification process for the 777X family remains a significant hurdle, and any further delays could inflate production costs. Nevertheless, achieving critical production benchmarks could position Boeing favorably to capture the next upcycle in the cargo market with a high-payload, long-range, and environmentally efficient freighter.

The eventual introduction of the 777-8F will not only enhance cargo capacity but also impact passenger travel indirectly. Although the 777-8F is specifically designed for cargo transport, its production shares resources and systems with the passenger variant of the 777X. As airlines increasingly rely on cargo operations for revenue, the new freighter model will provide greater flexibility and potential for increased earnings.

Boeing’s ongoing commitment to innovation and production efficiency in the 777-8F Freighter program demonstrates its determination to meet evolving market demands while navigating the complexities of the aerospace industry. As the company progresses towards the anticipated 2028 service entry, the focus on robust manufacturing practices and strategic partnerships will be crucial for its success.

-

Business1 week ago

Business1 week agoIconic Sand Dollar Social Club Listed for $3 Million in Folly Beach

-

Politics1 week ago

Politics1 week agoAfghan Refugee Detained by ICE After Asylum Hearing in New York

-

Health1 week ago

Health1 week agoPeptilogics Secures $78 Million to Combat Prosthetic Joint Infections

-

Science1 week ago

Science1 week agoResearchers Achieve Fastest Genome Sequencing in Under Four Hours

-

Lifestyle1 week ago

Lifestyle1 week agoJump for Good: San Clemente Pier Fundraiser Allows Legal Leaps

-

Health1 week ago

Health1 week agoResearcher Uncovers Zika Virus Pathway to Placenta Using Nanotubes

-

World1 week ago

World1 week agoUS Passport Ranks Drop Out of Top 10 for First Time Ever

-

Business1 week ago

Business1 week agoSan Jose High-Rise Faces Foreclosure Over $182.5 Million Loan

-

World1 week ago

World1 week agoRegional Pilots’ Salaries Surge to Six Figures in 2025

-

Science1 week ago

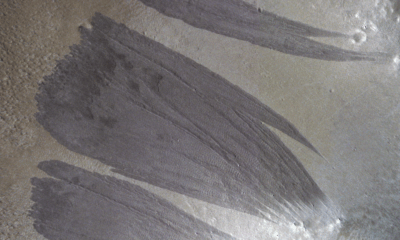

Science1 week agoMars Observed: Detailed Imaging Reveals Dust Avalanche Dynamics

-

Entertainment1 week ago

Entertainment1 week agoJennifer Lopez Addresses A-Rod Split in Candid Interview

-

Top Stories1 week ago

Top Stories1 week agoChicago Symphony Orchestra Dazzles with Berlioz Under Mäkelä