Business

Techman Robot Unveils AI Innovations at iREX 2025 in Tokyo

Techman Robot introduced groundbreaking technologies in manufacturing efficiency at the International Robot Exhibition (iREX) 2025, held from March 15 to March 18 at Tokyo Big Sight. The exhibition showcased the company’s commitment to enhancing productivity through its High-Speed AI Flying Trigger Inspection and “Auto AI Training” technology. This advancement marks a significant shift towards zero-downtime production processes.

The High-Speed AI Flying Trigger Inspection system, the highlight of Techman Robot’s presentation, emphasizes the company’s leadership in collaborative robotics. By utilizing the Nvidia Omniverse platform, this system enables precise simulation and optimization of robot motion control and AI visual algorithms before physical implementation. This feature ensures real-time responsiveness and exceptional precision during operations. The system integrates high-speed motion with advanced AI vision, allowing for instantaneous defect detection and quality control while workpieces are still in motion.

According to Techman Robot, companies that adopt this innovative system can expect to reduce inspection times by an impressive 40 to 50 percent. This reduction significantly optimizes cycle times and enhances overall production efficiency, particularly for high-standard applications such as automotive seat components and server assembly. The technology also minimizes human error and decreases labor costs, aligning with the rigorous “zero defect” standards prevalent in the Japanese automotive and precision manufacturing sectors.

Streamlining AI Adoption with Auto Training Technology

In response to the industry’s challenges regarding complex and time-consuming AI integration, Techman Robot unveiled its “Auto AI Training” technology. This new solution can cut the time needed for implementing AI visual inspection by up to 90 percent.

The technology allows frontline production staff to label, train, and optimize AI vision models in real-time, significantly reducing dependence on specialized AI engineers. This acceleration facilitates faster adjustments along production lines. Demonstrating this capability, Techman Robot showcased a printer inspection demonstration that combines collaborative robots (cobots), grippers, and AI vision to conduct rapid, high-precision quality checks on intricate electronic assemblies.

To address the growing demand for quick implementation and rapid return on investment, Techman Robot launched its “Instant Cobot Ready” automation suite. A key component of this suite is the Instant Palletizer, designed to handle payloads of up to 35 kg. This system supports continuous stacking operations, offering logistics and packaging sectors an efficient “plug-and-play” solution that maximizes investment efficiency and accelerates automation transformation.

Dr. Scott Huang, Chief Operating Officer of Techman Robot, emphasized the importance of iREX as a platform for showcasing innovative robotics technologies. He stated, “Techman Robot is not merely a manufacturer of collaborative robots; we are a leader in AI-driven automation solutions. Through close collaboration with global partners like Nvidia, we aim to provide AI collaborative applications that are easier to adopt and yield faster results, guiding the manufacturing industry into the next wave of smart upgrades.”

As the global manufacturing landscape continues to evolve, Techman Robot’s latest offerings position the company at the forefront of technological advancements. The integration of high-speed AI inspection systems and streamlined AI training methodologies represents a pivotal moment for manufacturers seeking to enhance productivity and maintain competitive advantage.

-

Science1 month ago

Science1 month agoUniversity of Hawaiʻi Leads $25M AI Project to Monitor Natural Disasters

-

Science2 months ago

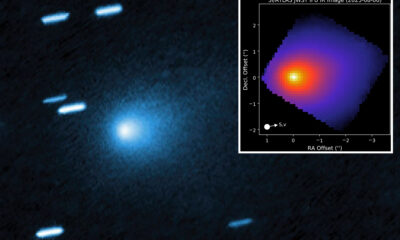

Science2 months agoInterstellar Object 3I/ATLAS Emits Unique Metal Alloy, Says Scientist

-

Science2 months ago

Science2 months agoResearchers Achieve Fastest Genome Sequencing in Under Four Hours

-

Business2 months ago

Business2 months agoIconic Sand Dollar Social Club Listed for $3 Million in Folly Beach

-

Politics2 months ago

Politics2 months agoAfghan Refugee Detained by ICE After Asylum Hearing in New York

-

Business2 months ago

Business2 months agoMcEwen Inc. Secures Tartan Lake Gold Mine Through Acquisition

-

Health2 months ago

Health2 months agoPeptilogics Secures $78 Million to Combat Prosthetic Joint Infections

-

Science2 months ago

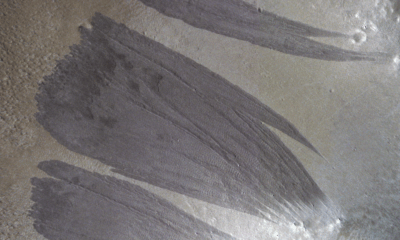

Science2 months agoMars Observed: Detailed Imaging Reveals Dust Avalanche Dynamics

-

Lifestyle2 months ago

Lifestyle2 months agoJump for Good: San Clemente Pier Fundraiser Allows Legal Leaps

-

Health2 months ago

Health2 months agoResearcher Uncovers Zika Virus Pathway to Placenta Using Nanotubes

-

Entertainment2 months ago

Entertainment2 months agoJennifer Lopez Addresses A-Rod Split in Candid Interview

-

World2 months ago

World2 months agoUS Passport Ranks Drop Out of Top 10 for First Time Ever